Jiangsu Changyi Electro-technique Co., Ltd. established in 1989, our electric motor production facility covers an area of 8,000 square meters. We have passed the ISO9001 Quality Management System Certification.

We have a highly professional design staff that are specially trained in graphics software operation. They continuously improve their motor designs by learning from the problems that they meet.

Our workshops include a stamping workshop, machining workshop, motor manufacturing workshop and geared motor workshop. Each workshop undergoes routine inspections, and records test results. We can monthly produce 40,000 units of motors.

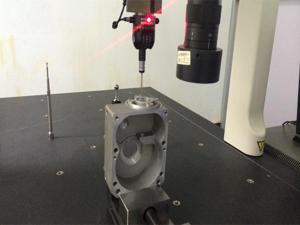

In order to deliver a strict quality monitoring system, Jiangsu Changyi established a professional quality assurance department. In this department, there are advanced two-dimensional and three-dimensional coordinate-measuring machines. These measurement instruments could be used to deliver an overall inspection for complex or precise workpieces.

Automatic wire wrapping Each automatic wire wrap machine supports a production capacity of 500pcs.

The hydraulic press is mainly used for inserting the shaft into the rotor core, its production capacity can reach 500pcs per person per shift.

We use automatic spot welding machines for welding the commutators, and 900pcs can be well welded per person per shift.

The automatic electric rotor painting machine can be used for painting different types of rotors. It has a baking time of at least two hours, this machine can work on 240 rotors at one time and it can paint 700 to 800 rotors per day.

The dynamic balance machine is used to detect and ensure the dynamic balancing of the rotor. It can fulfill the balancing of 400pcs per person per shift.

The comprehensive armature testing machine detects the inter-turn winding wave and the breakdown strength of the rotor with windings, and can test 1000pcs per person per shift.